SPORTMASTER INNOVATION CENTER

The main function of the Innovation Center is to develop new innovative materials applied to Sportmaster’s products. Such as:

Thermal insulation materials for winter clothes

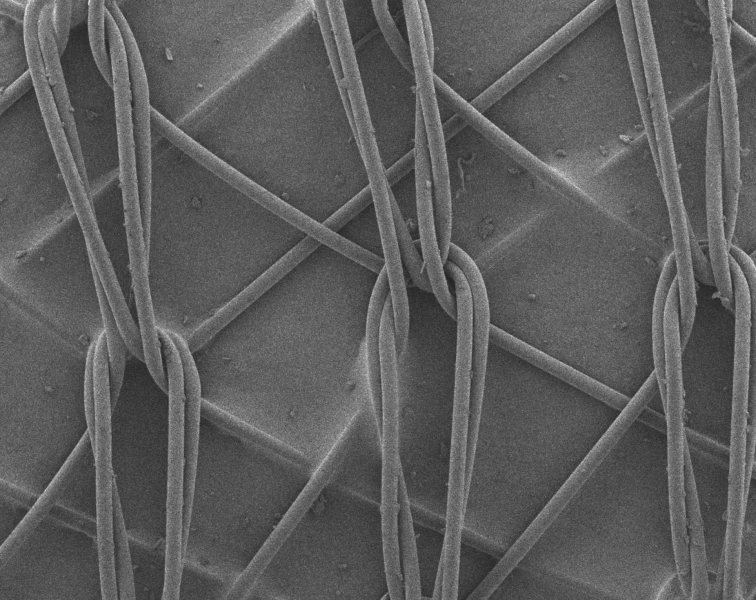

Functional printed fabrics

Fabrics with a positive body effect, that ensures better sport performance

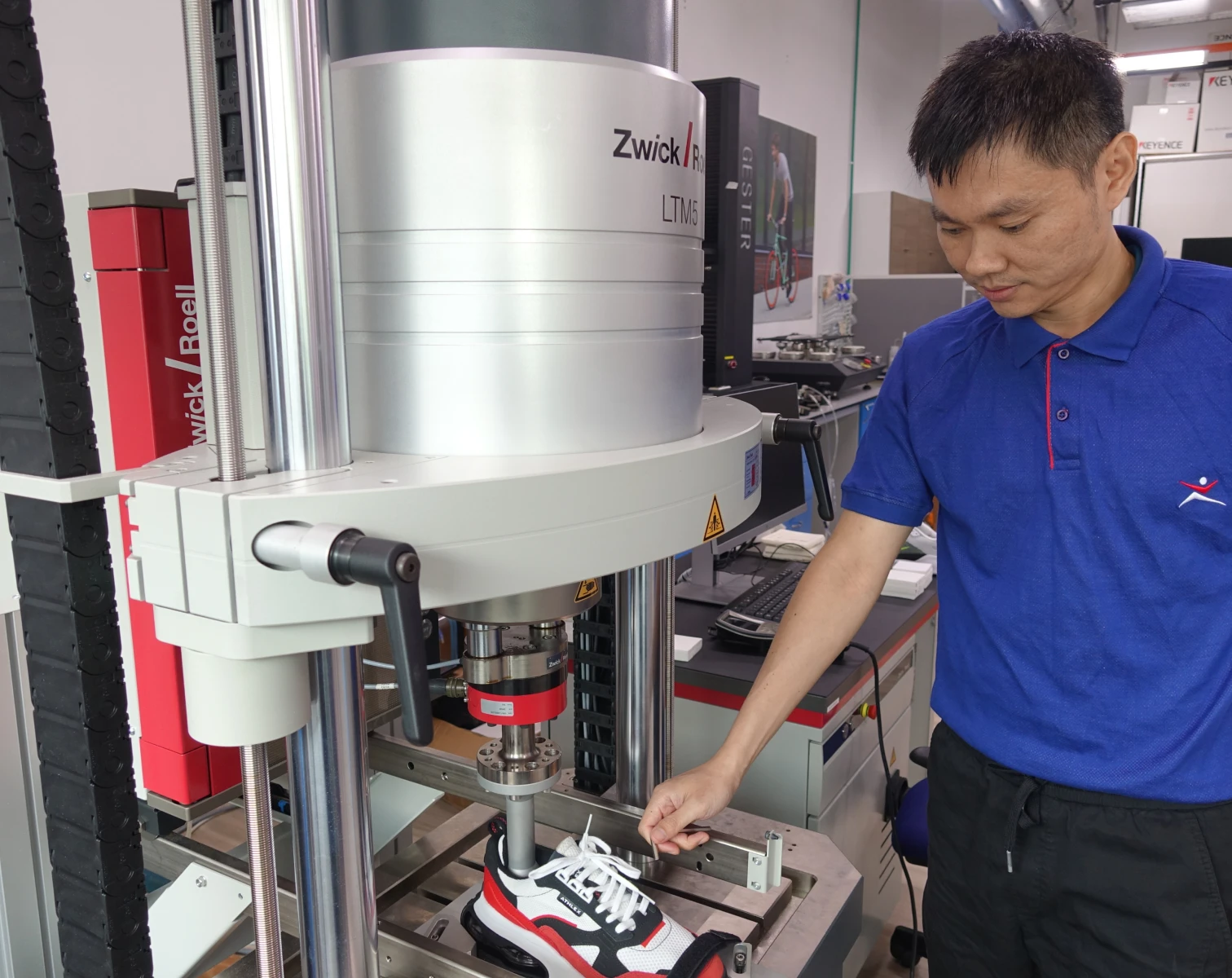

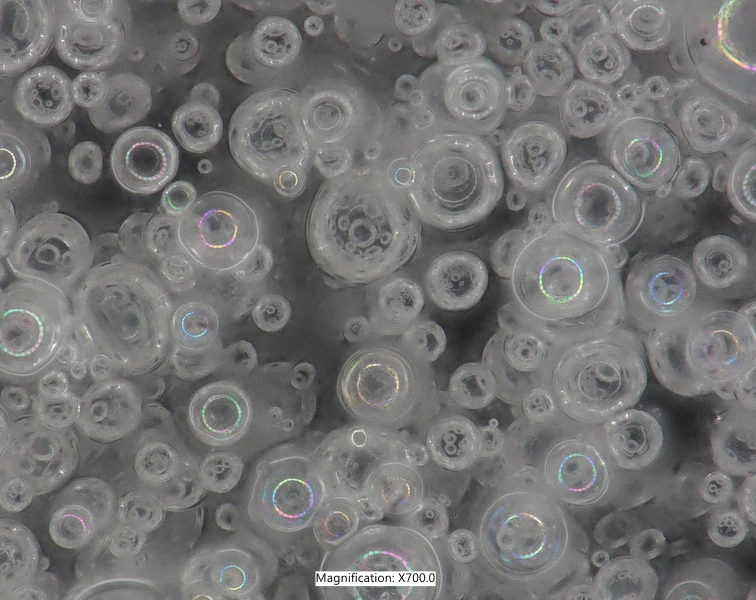

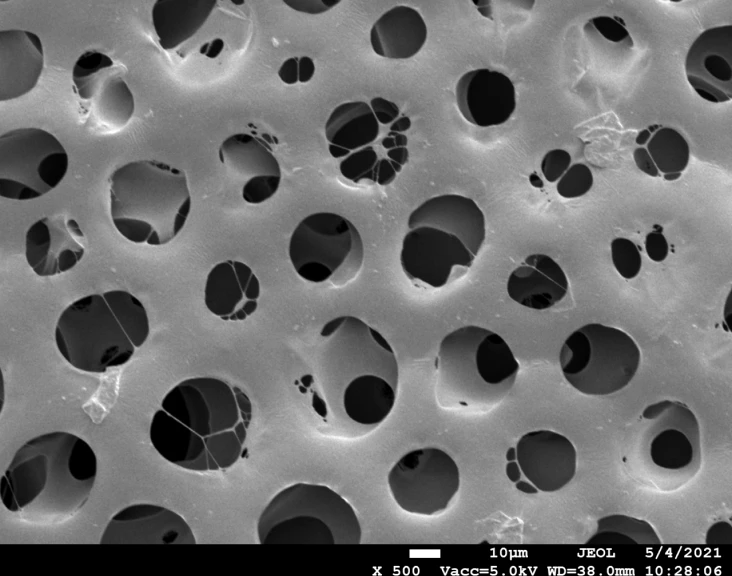

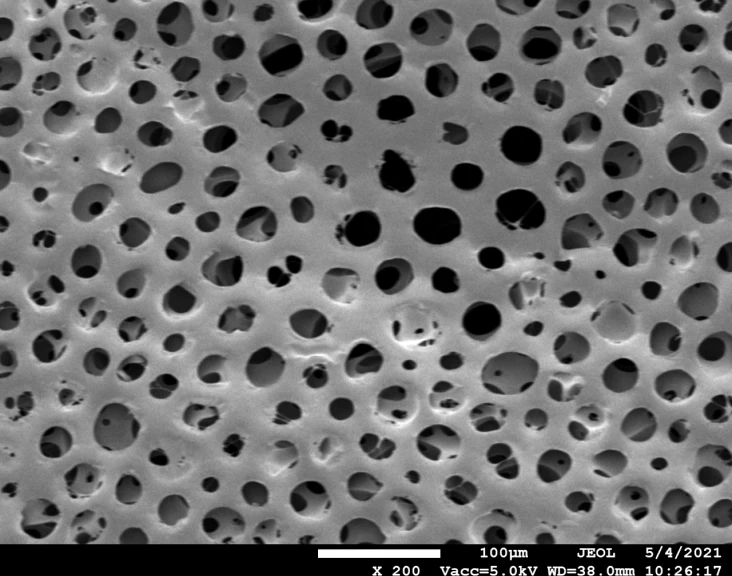

Foam compositions for footwear

High-performance membranes for outerwear

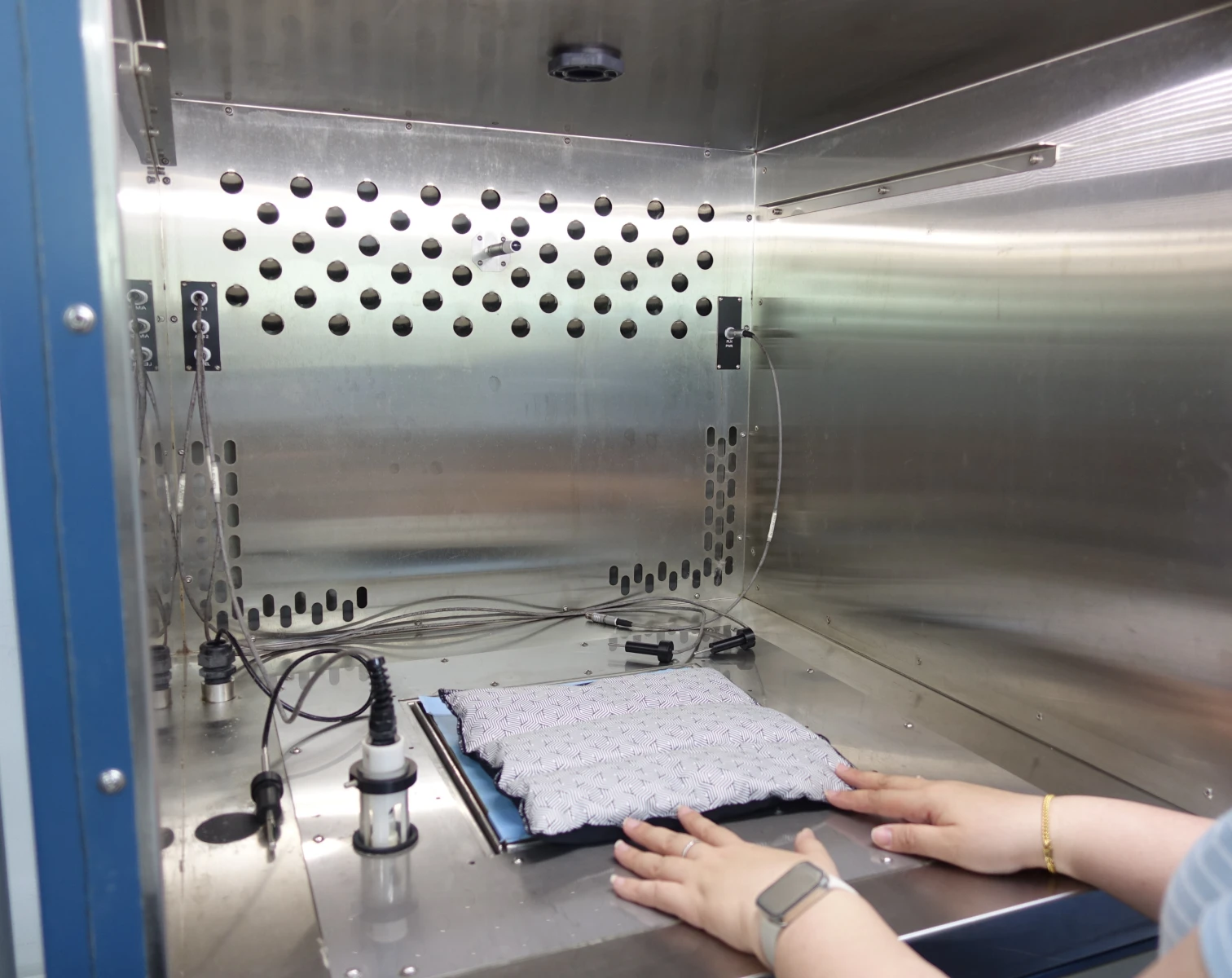

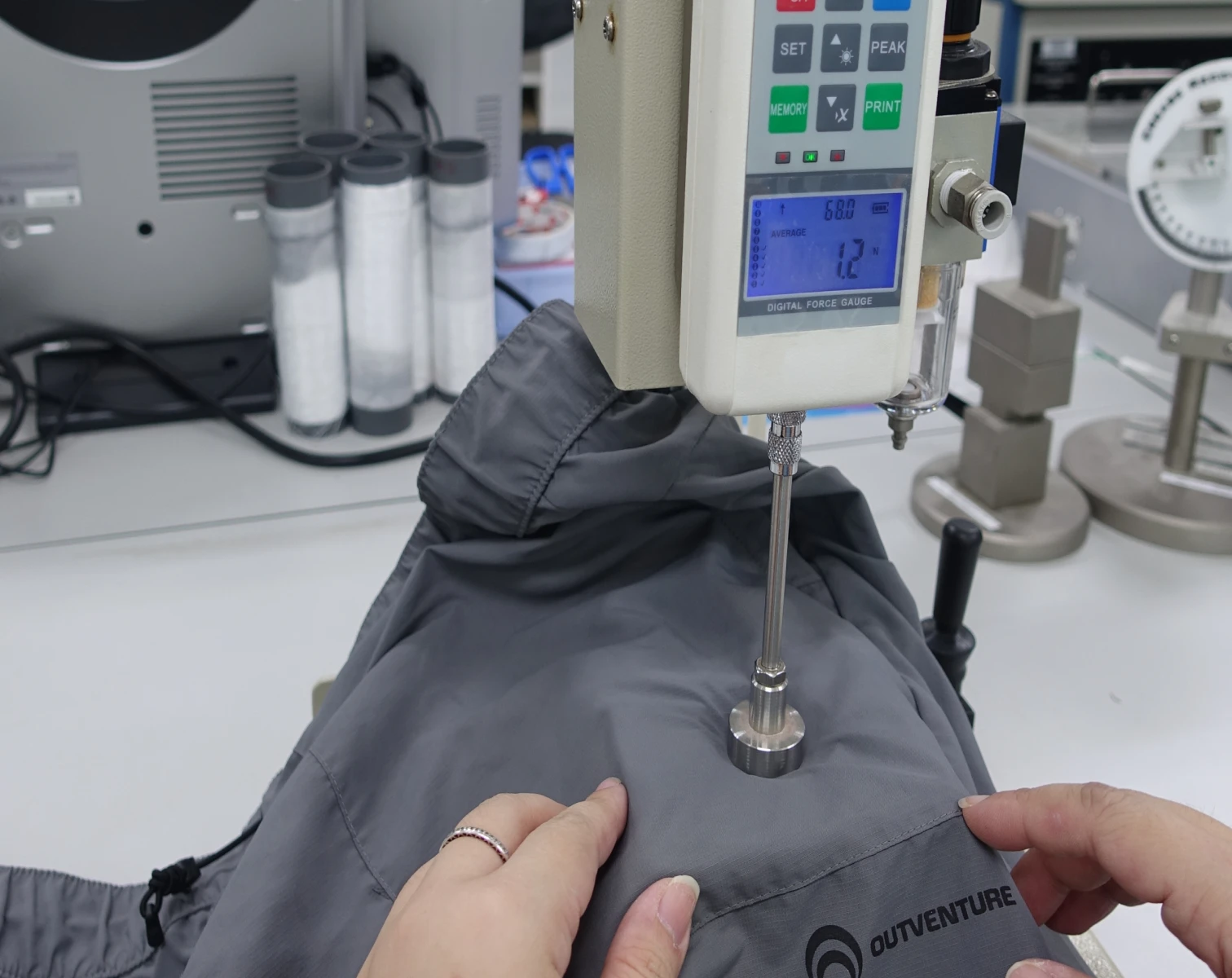

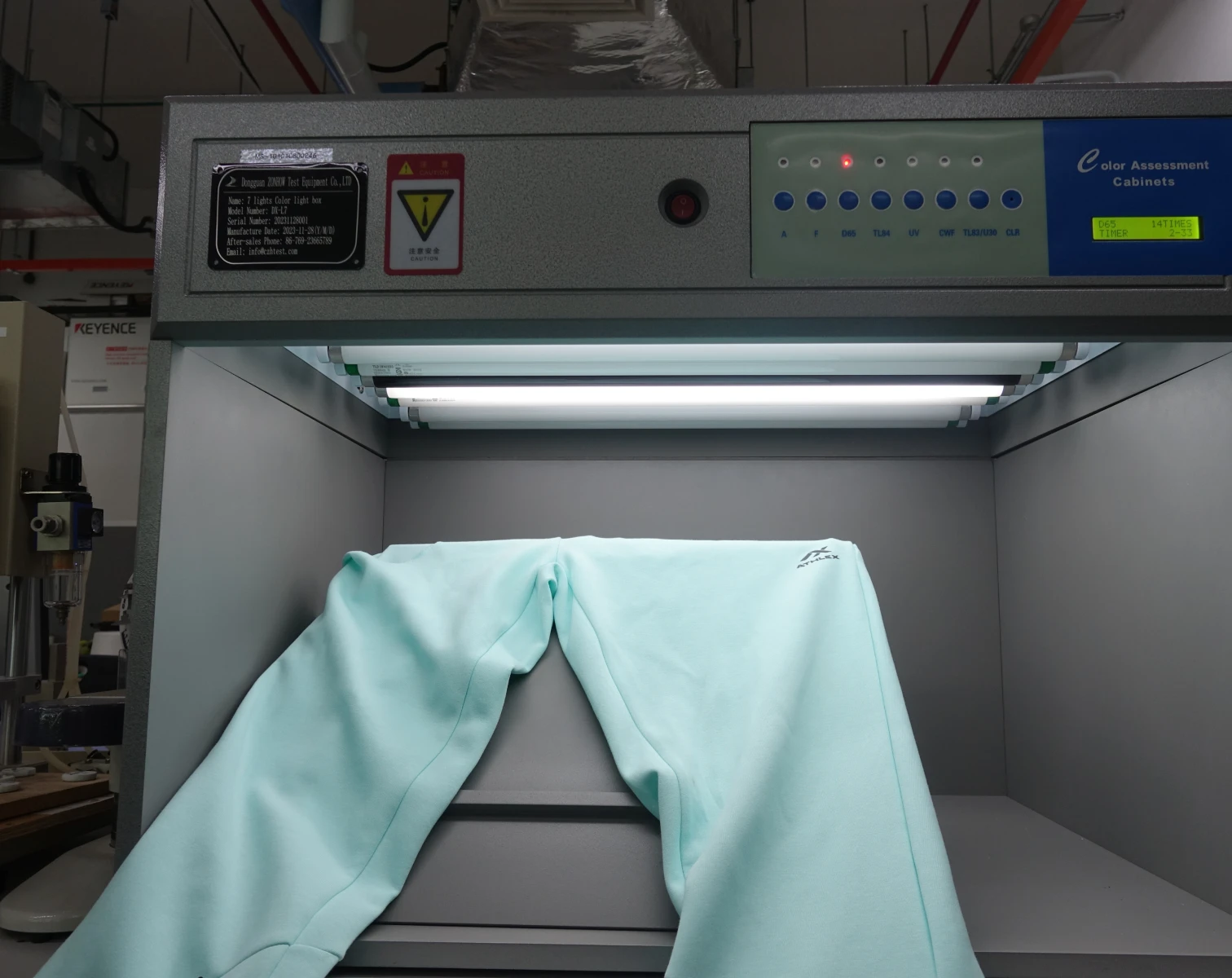

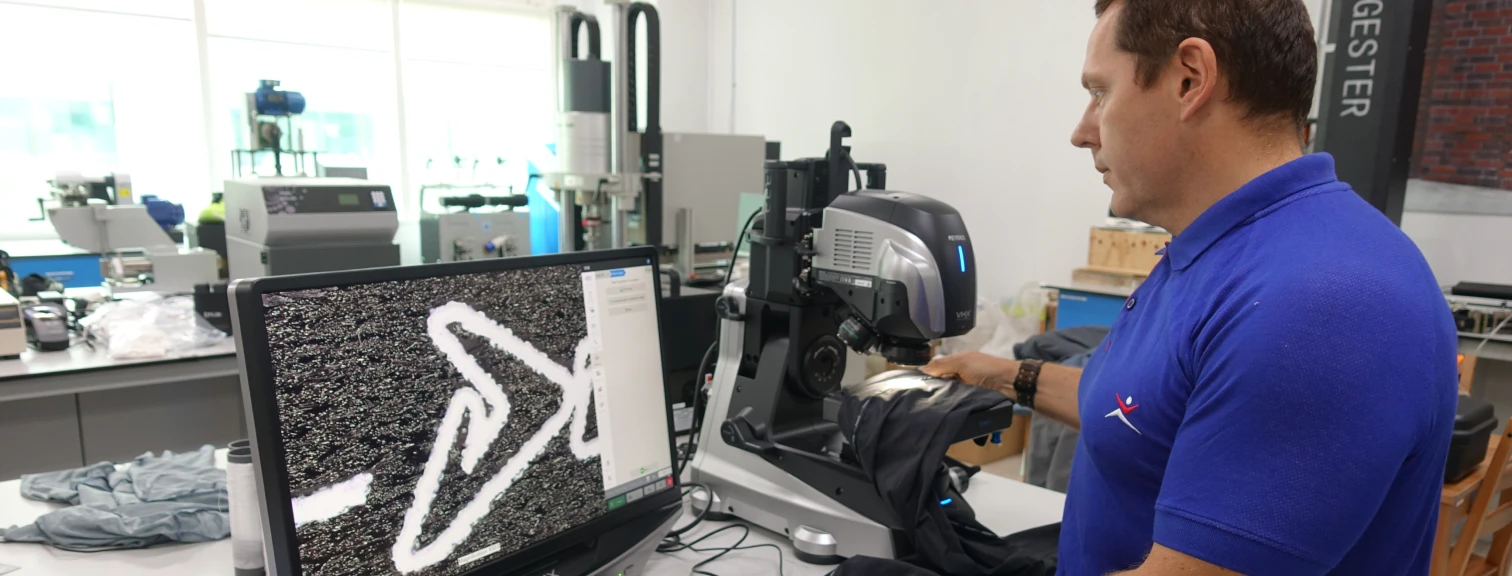

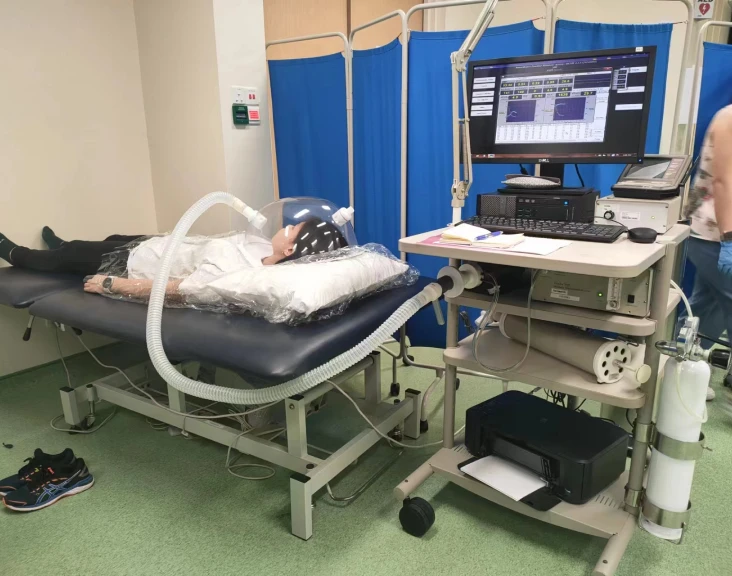

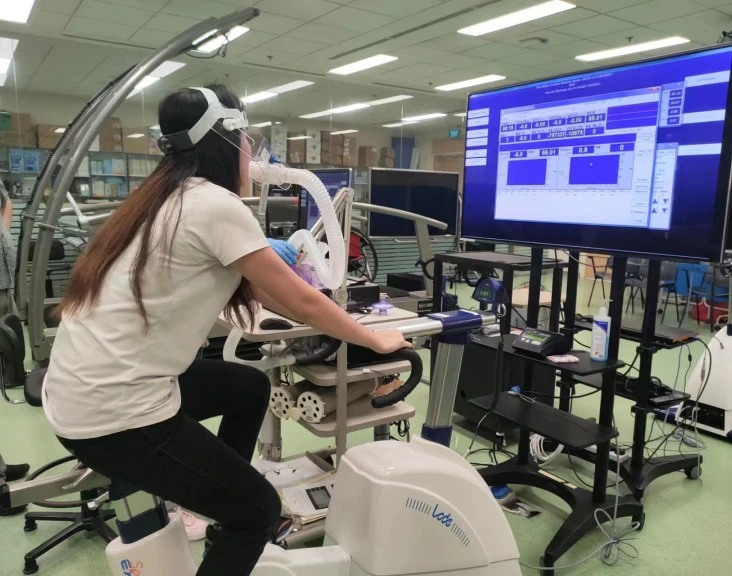

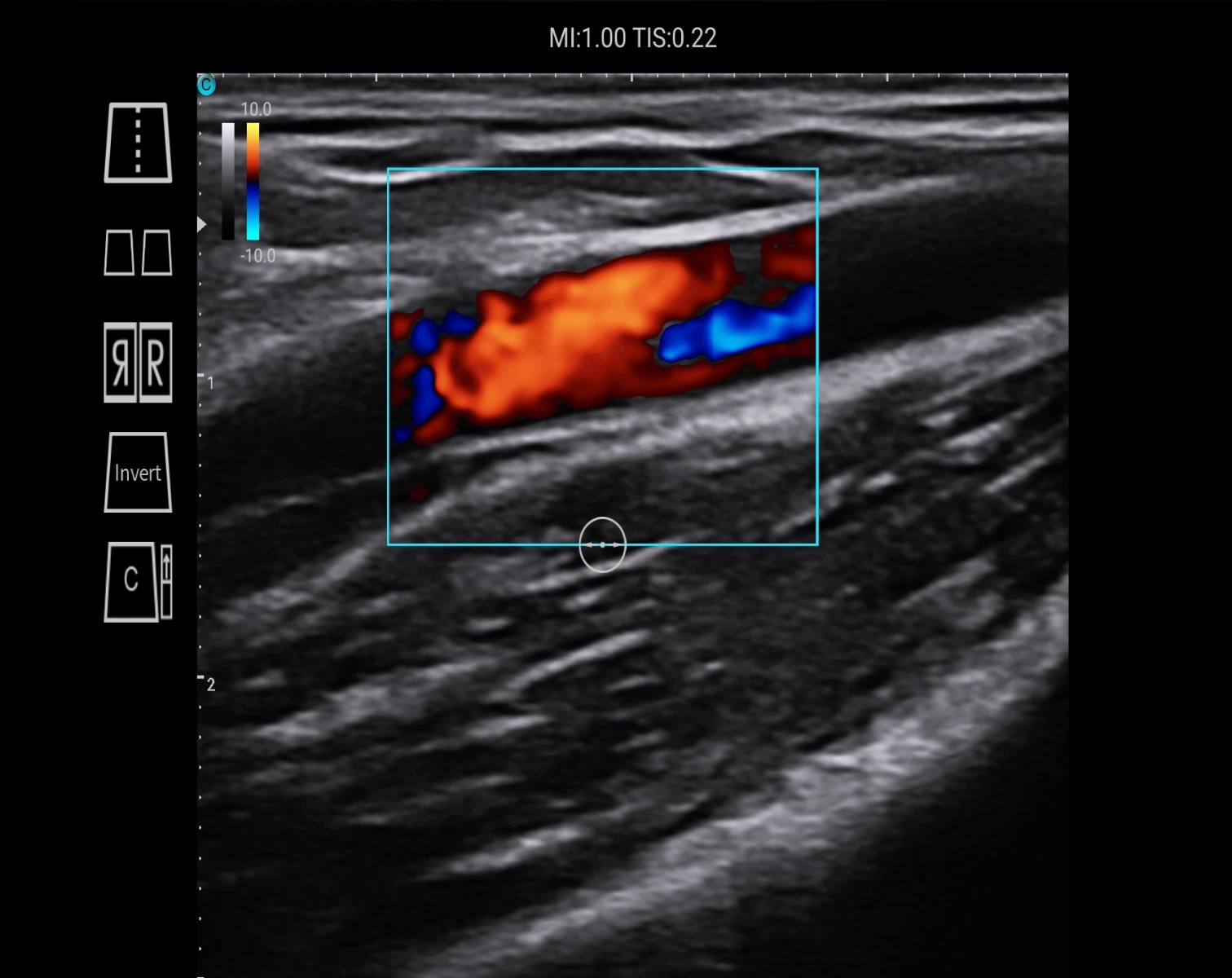

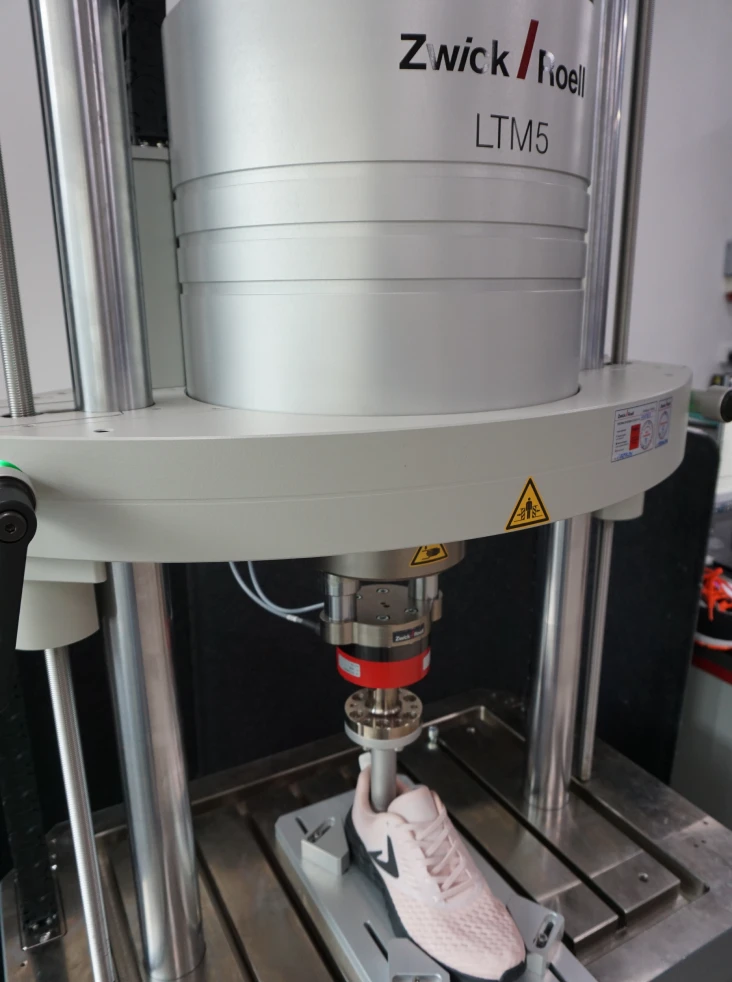

Testing of product properties

Different tests are performed annually by employees of R&D Center

Technologies

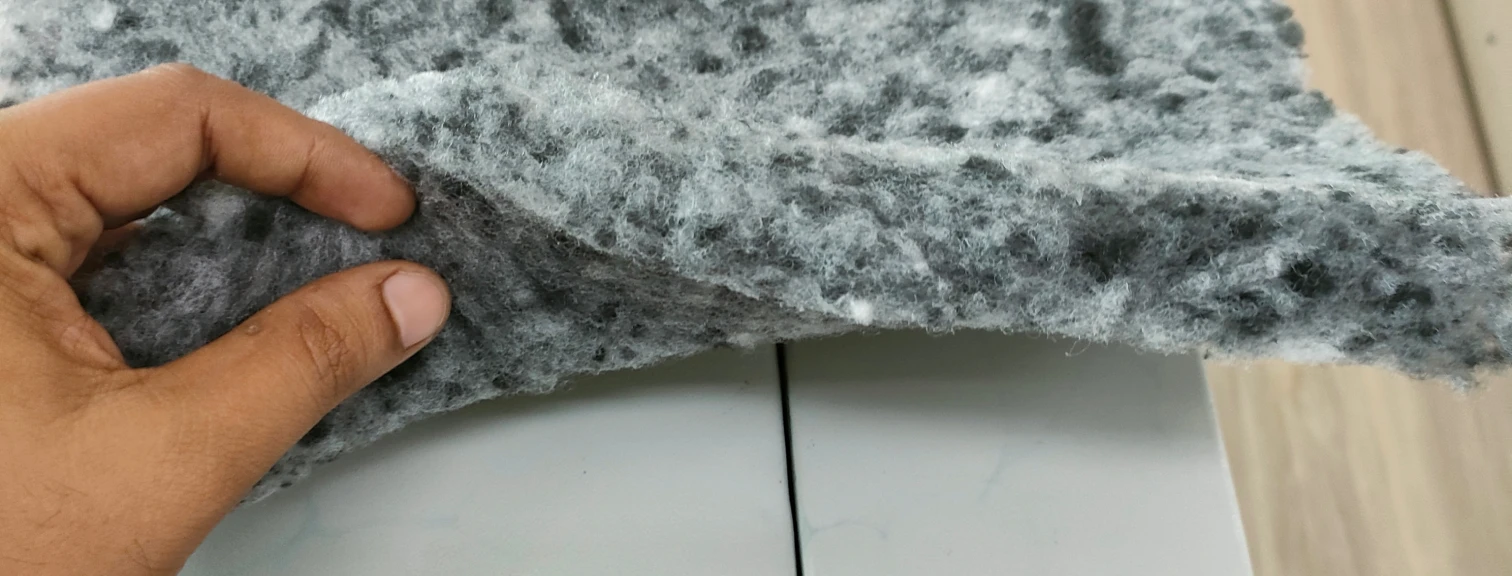

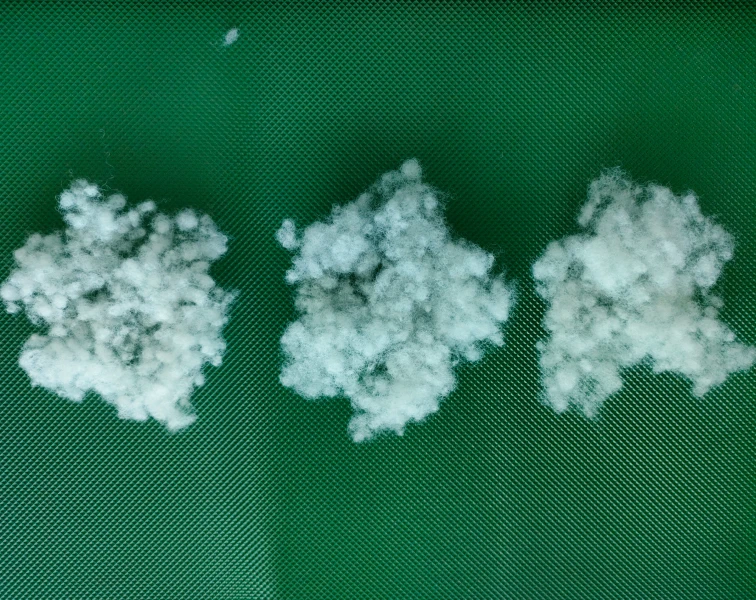

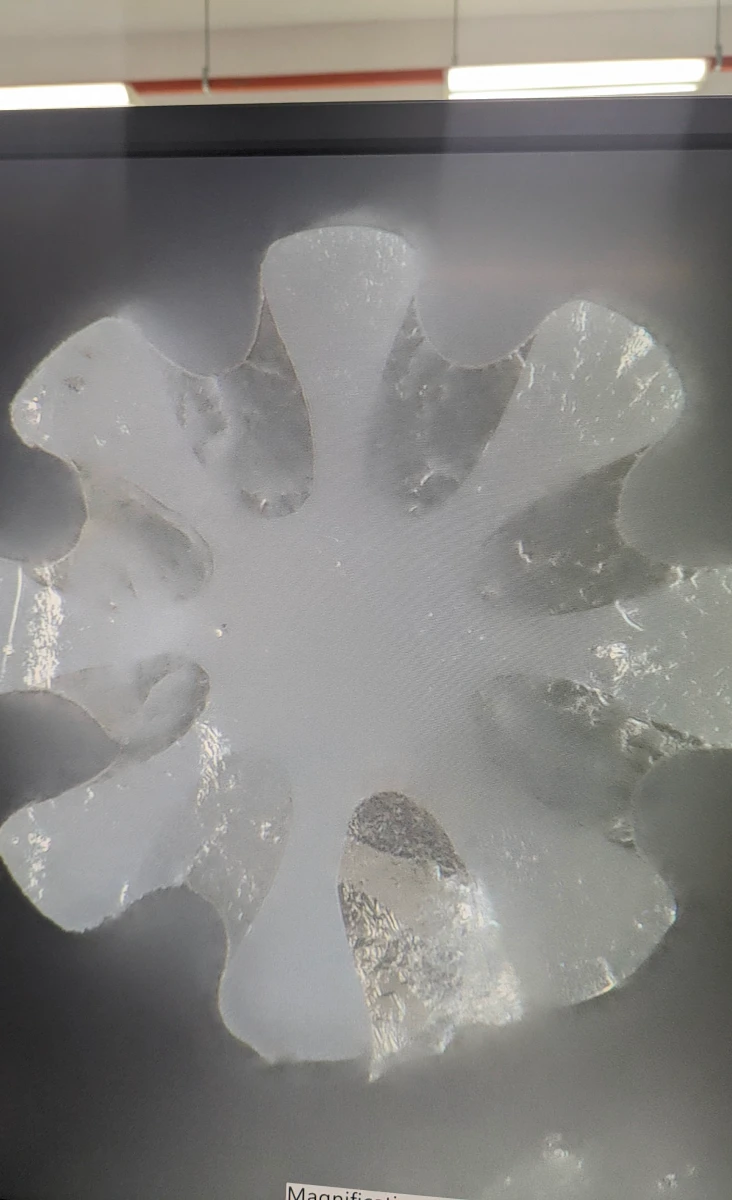

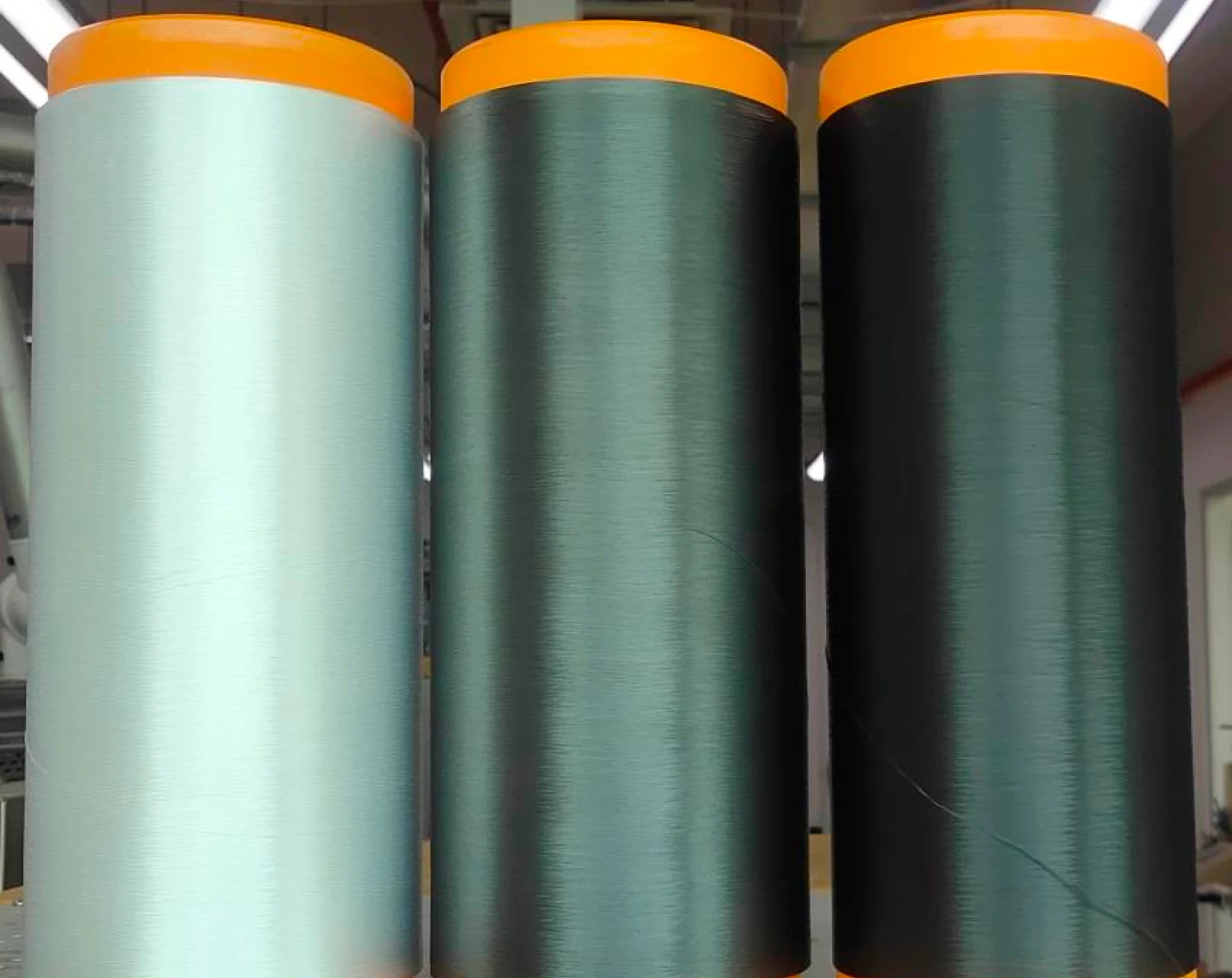

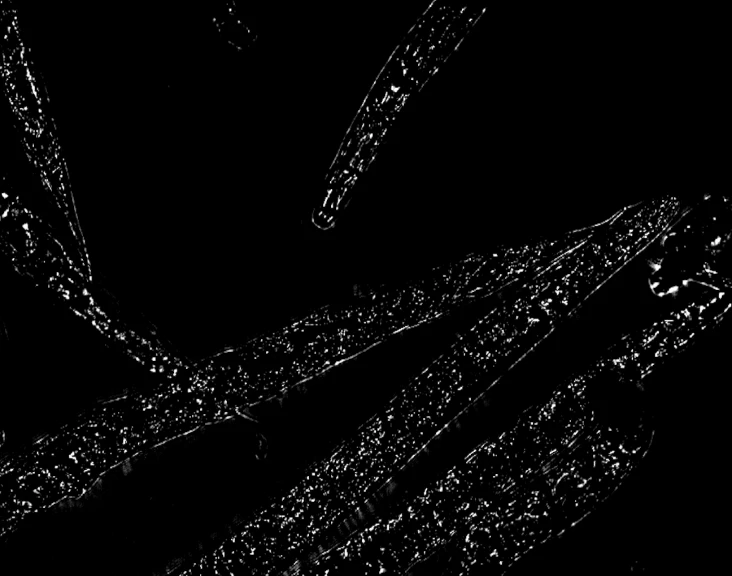

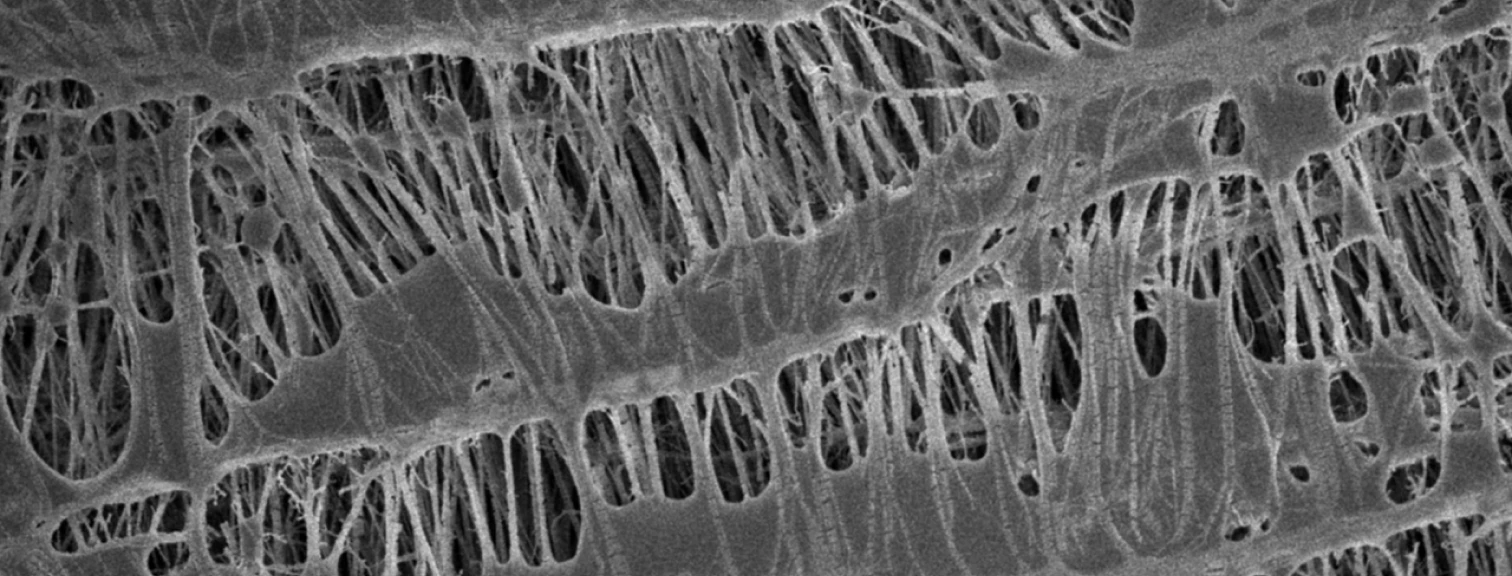

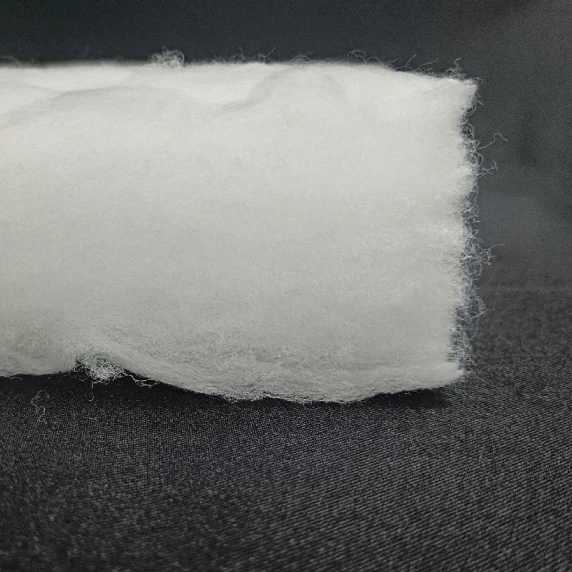

Alpha Cloud/Wave Fiber

Alpha Cloud is a lightweight, compact thermal insulation with a high recovery capacity

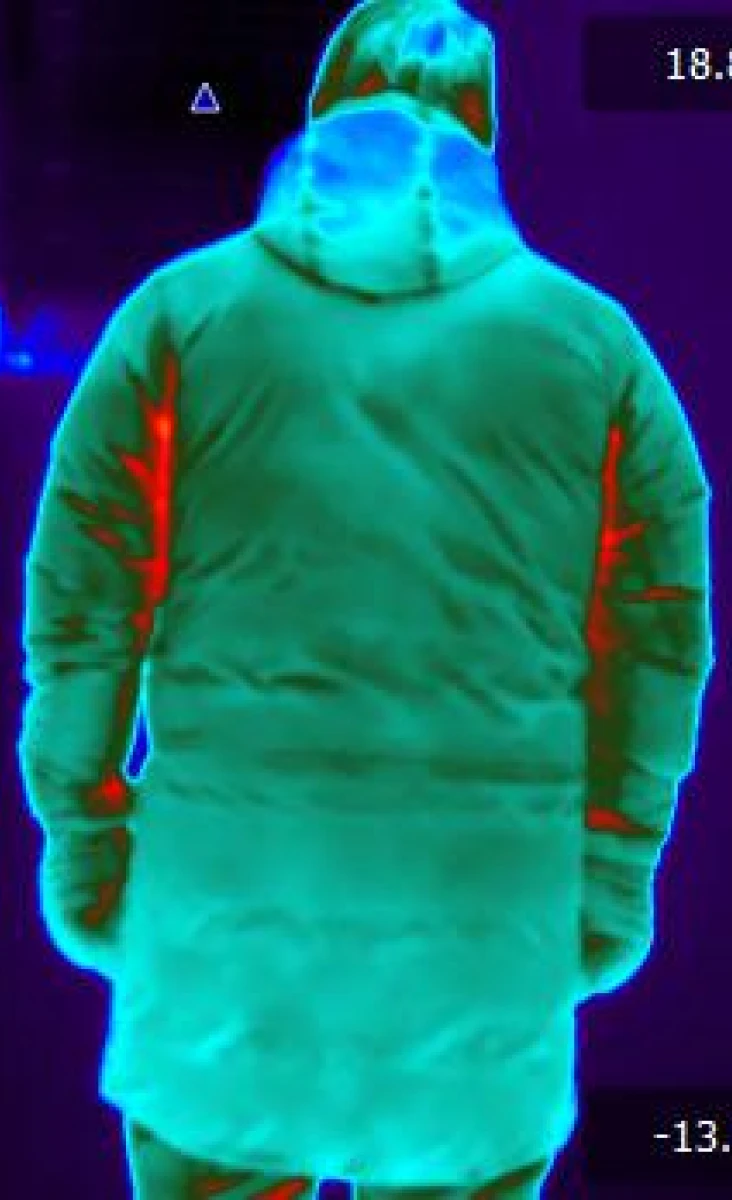

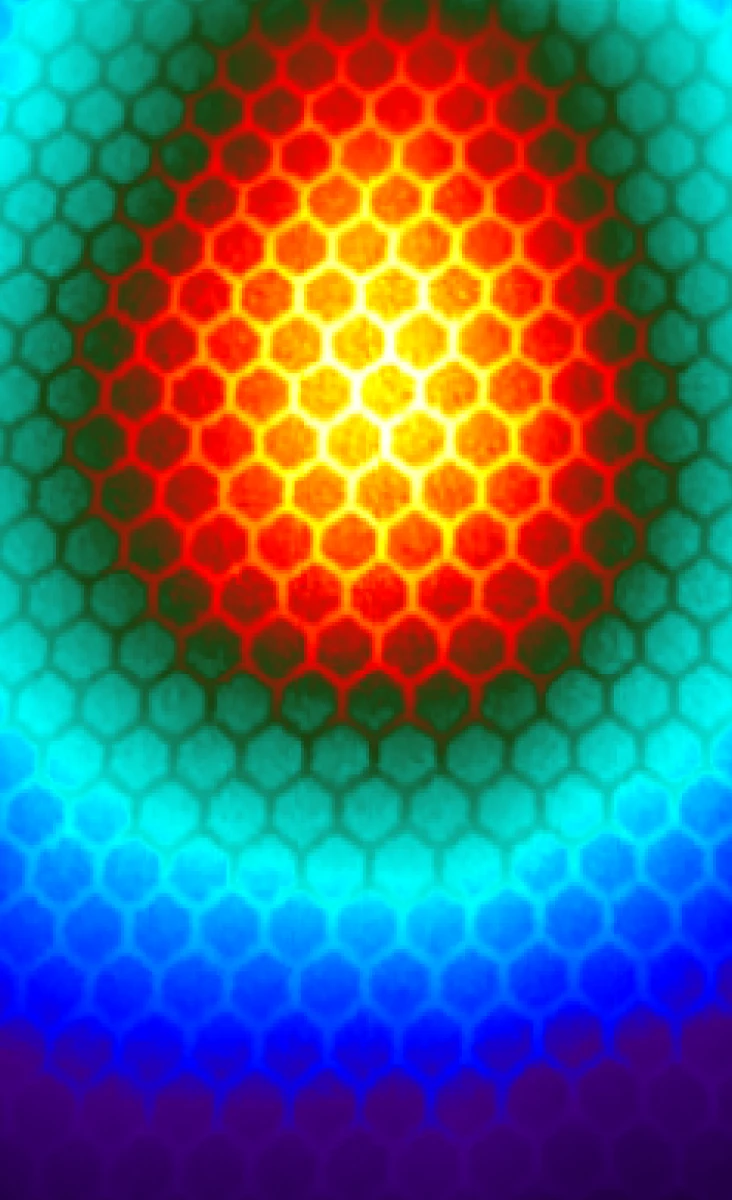

Pro Reflect

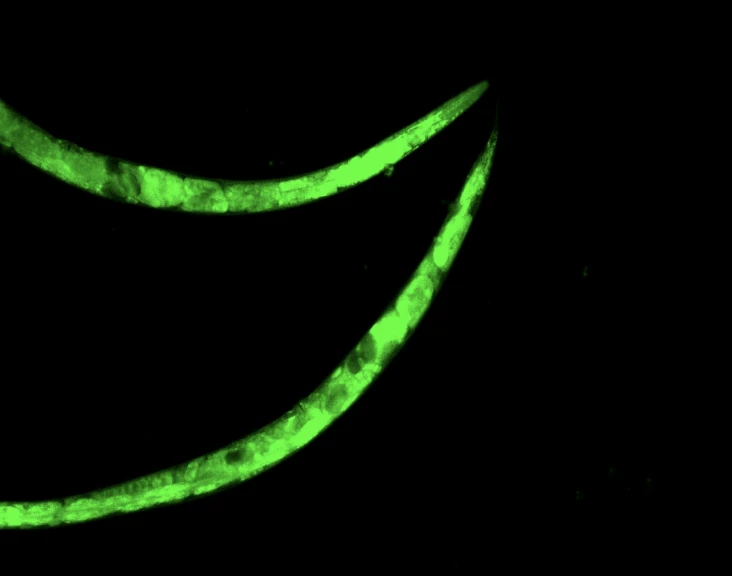

Pro Reflect is a unique thermal reflective technology that provides smart freeze protection

Pro Reflect consists of a smooth lining with monochrome graphics

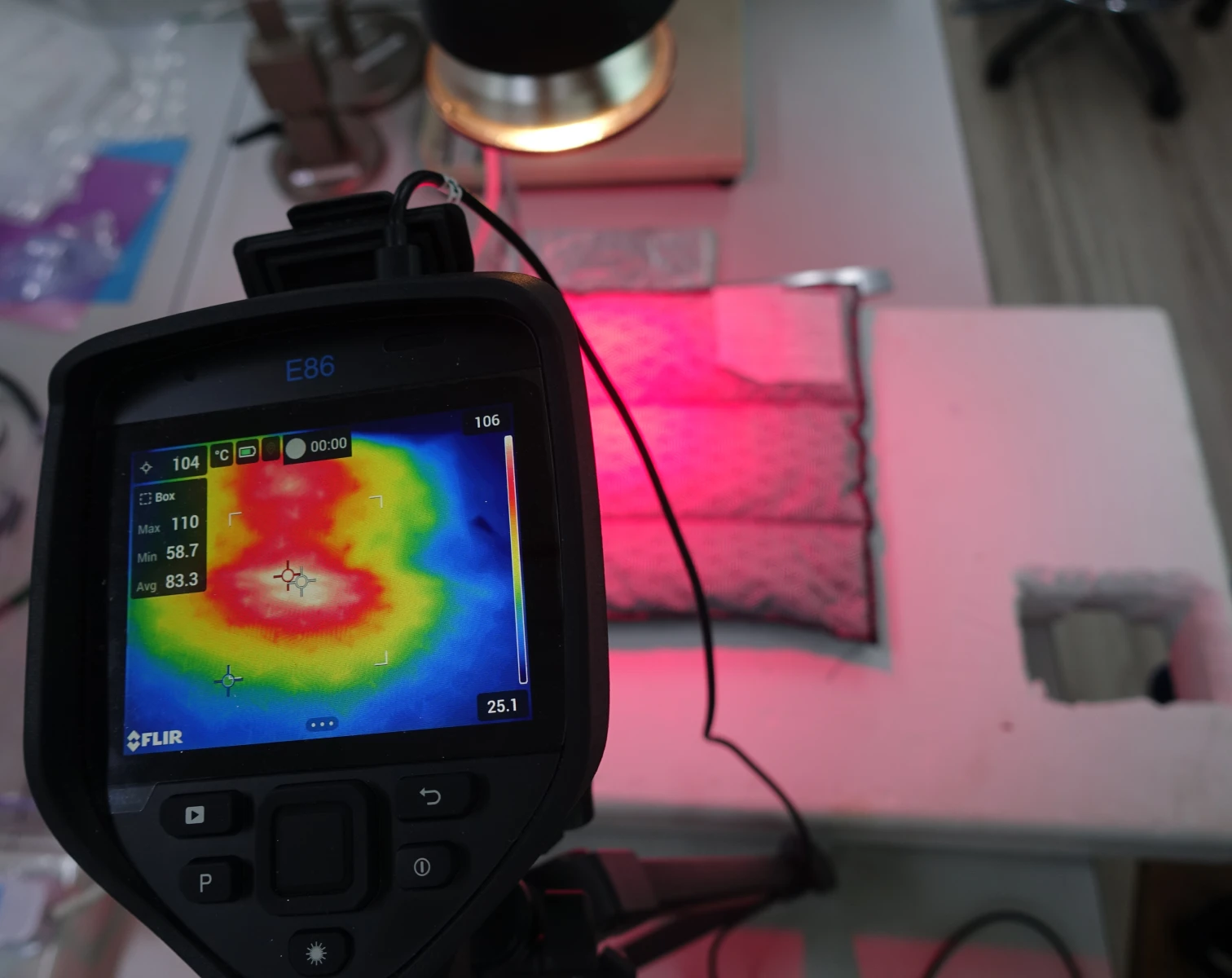

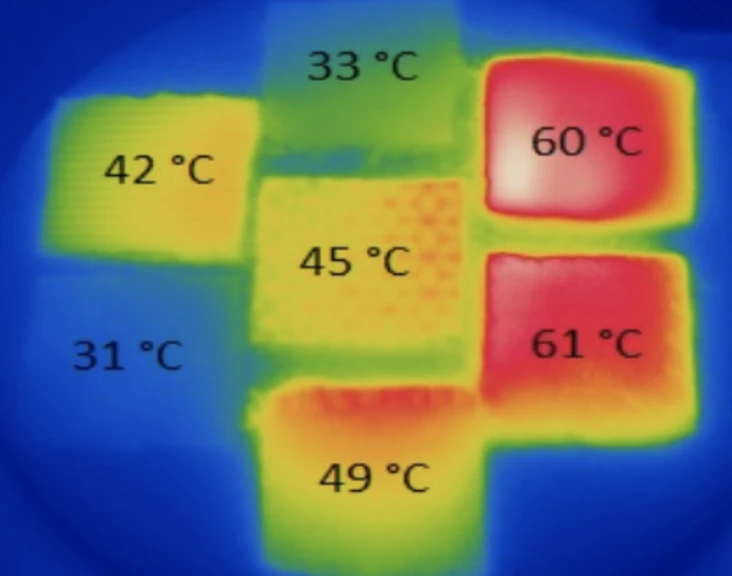

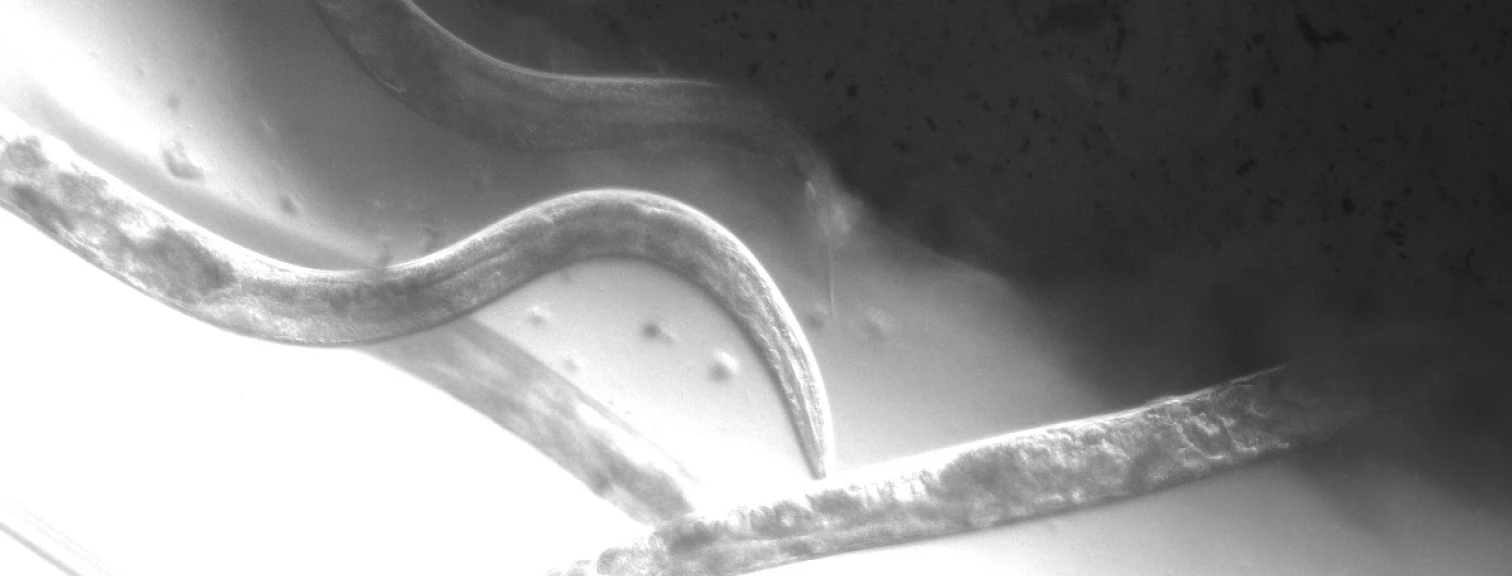

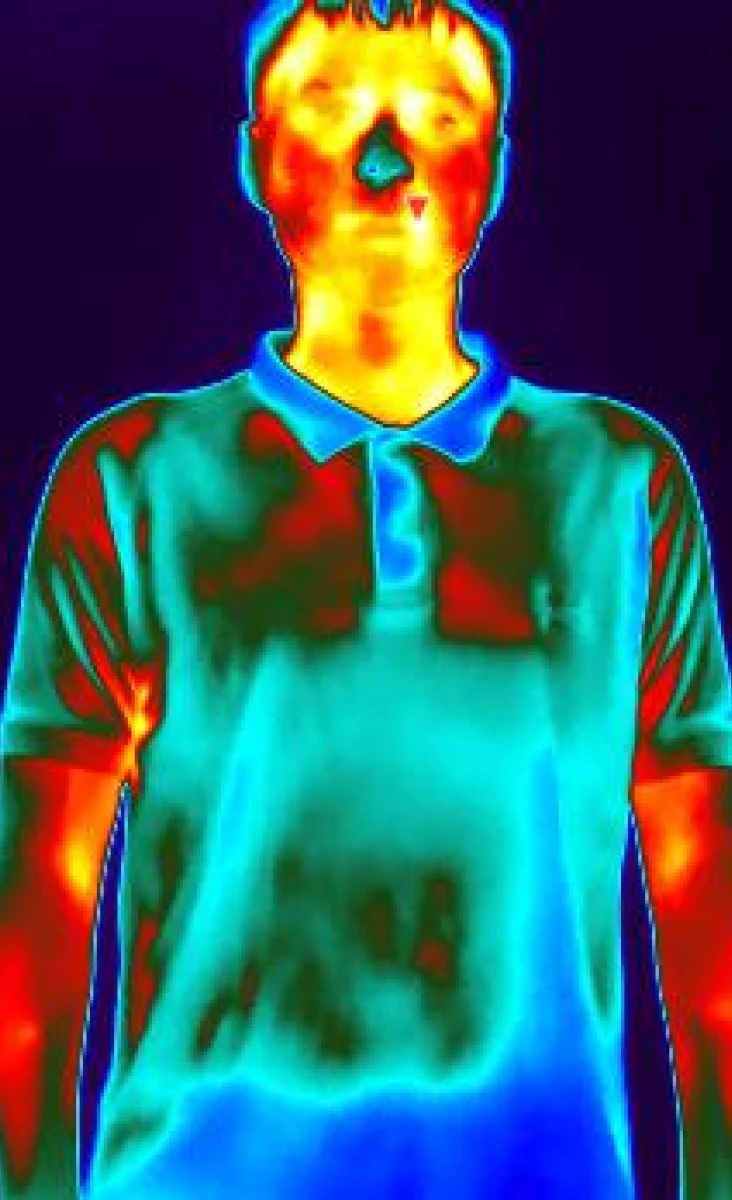

MOVI-warm

MOVI-WARM is a technology developed to keep you warm when exercising in cold weather, before and after physical activity

MOVI-WARM InfraRed BLACK technology keeps you warm and moves moisture away from your body. This guarantees comfort during workouts in cold weather

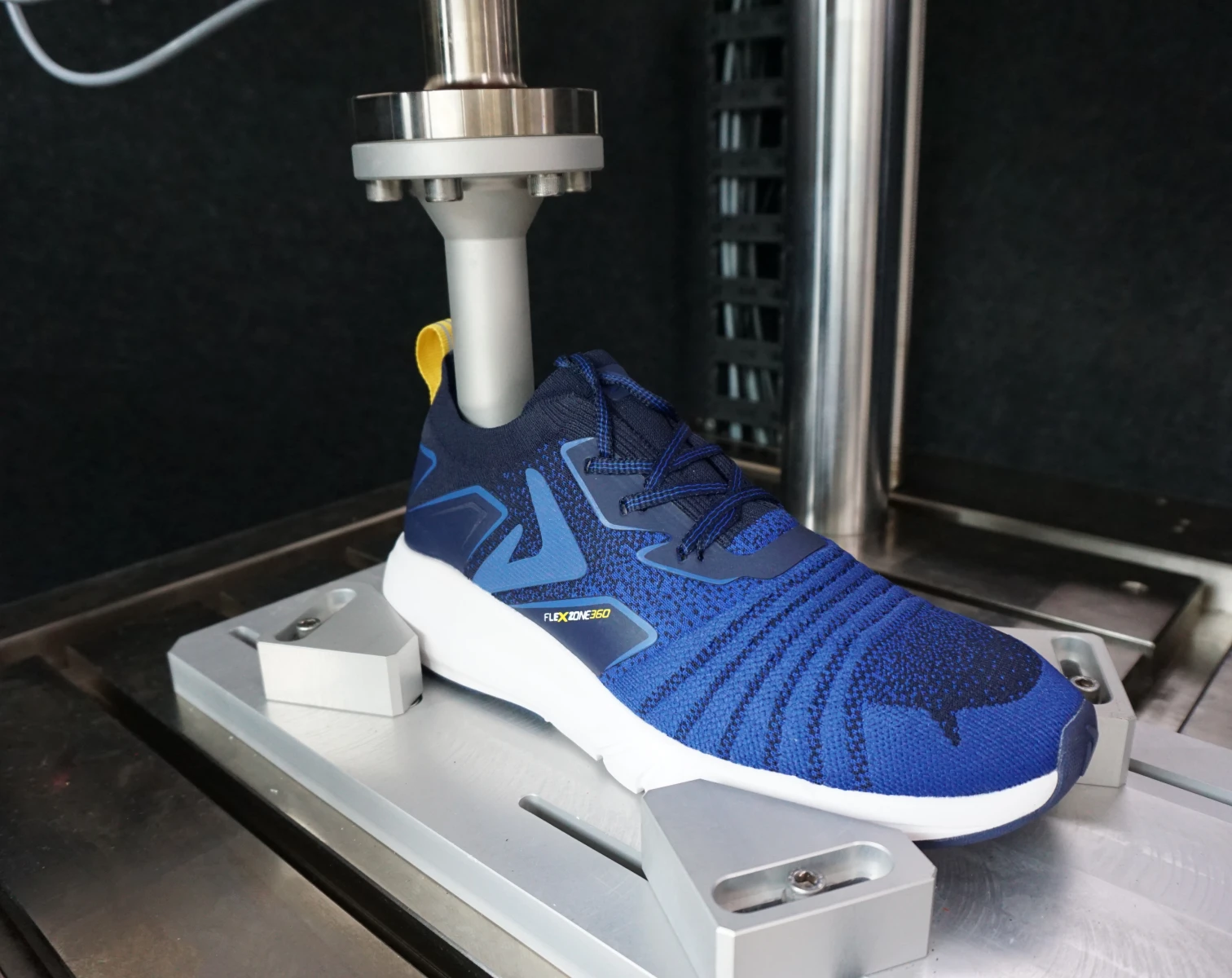

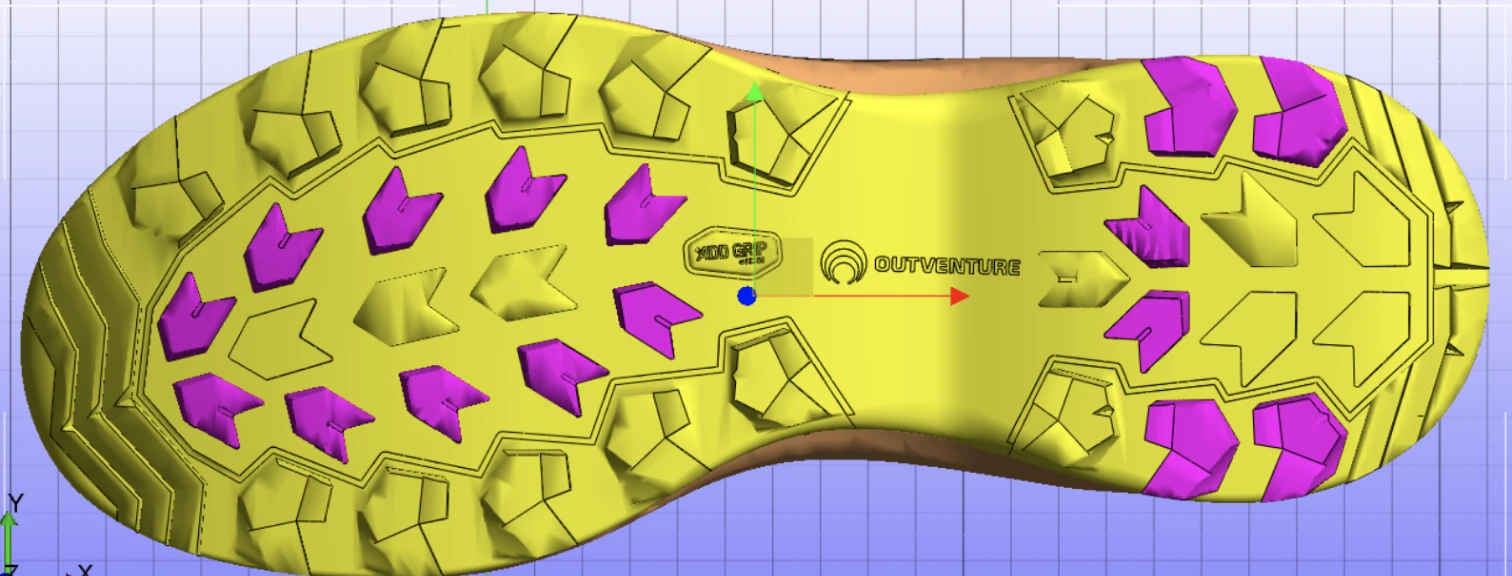

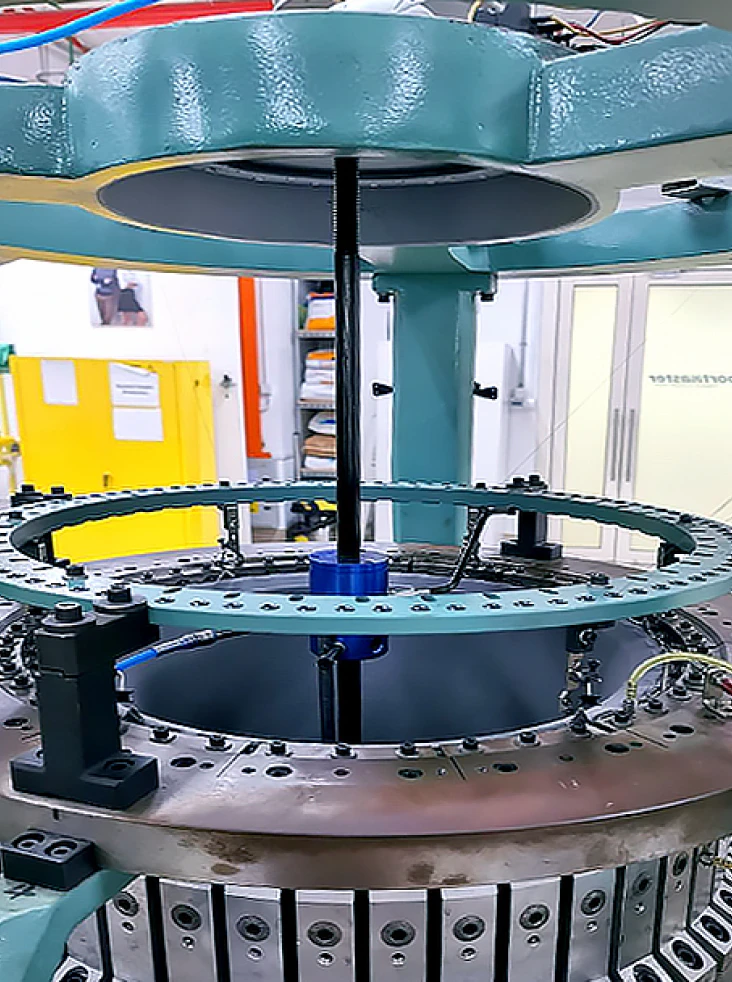

Flexzone360 2.0, Wet Ice Grip

Flexzone360 technology helps the sole to flex easily, allowing the foot to move in a completely natural way

Wet Ice Grip provides improved traction on snowy and icy surfaces due to the unique composition and geometry of the tread